Super User

Thermal compound is necessary to create a reliable transfer of heat from your computer's processor to its heatsink to keep your CPU from overheating. Junpus thermal compound does this with three unique shapes and sizes of pure silver particles to maximize particle-to-particle contact area and thermal transfer. It's optimized for use between modern high-power CPUs and high-performance heatsinks or water-cooling solutions.

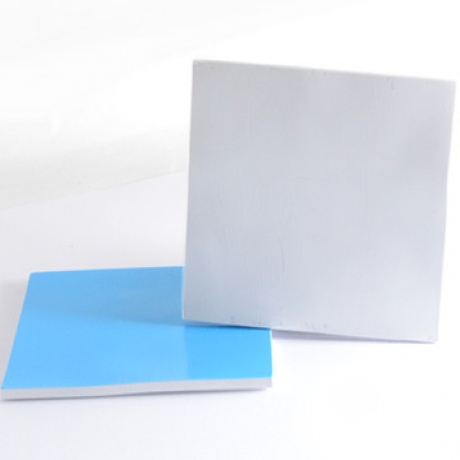

JP-P130 series is a gap filled with high-performance thermal conductivity material, mainly used in electronic devices and heat sinks or product transfer interface between the enclosure.

JP-P130 series has a good adhesive, flexible, good compression performance and excellent thermal conductivity.

So that it can be fully in use of electronic originals and the air discharge between the heat sink in order to achieve access to the full. Heat effect increased significantly.

JP-P130 Series also has a certain degree of self-adhesive, compared to ordinary thermal insulation material in the product installation process has brought great convenience, easy off, easy to operate.

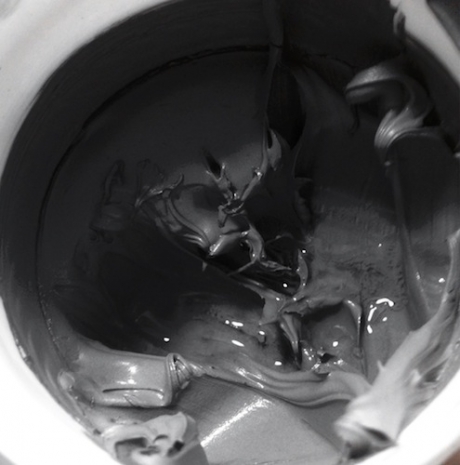

JP-DL800B Made with high-purity thermal conducting materials, JP-DL800B exhibits excellent thermal conduction thanks to its finer molecular structure produced by nanoscale treatment.

This product has the following superior properties such as high chemical stability, being non-corrosive, anti-oxidation, non-toxicity, non-volatility, non-flammability, and causing no irritation to human skin. It can withstand long-term storage, does not easily solidify, and can be readily implemented to the printing and coating process.

JP-T180 series is a gap filled with high-performance thermal conductivity material, mainly used in electronic devices and heat sinks or product transfer interface between the enclosure.

JP-T180 series has a good adhesive, flexible, good compression performance and excellent thermal conductivity.

So that it can be fully in use of electronic originals and the air discharge between the heat sink in order to achieve access to the full.

Heat effect increased significantly.

JP-T180 Series also has a certain degree of self-adhesive, compared to ordinary thermal insulation material in the product installation process has brought great convenience, easy off, easy to operate.

JPNS200 are formulated with Synthetic fluids and highly conductive ceramic fillers. These finely engineered compounds provide low bleed and solve the problems of contamination and migration associated with silicone based products.

They offer better stability for a longer life cycle with high thermal conductivity (2 W/m°K) and low thermal resistance (0.014 °C-in2/W).

Features:

1) We can tailor-make the most suitable blisters for your products,Blister Box, Plastic Blister, Vacuum Formed Blister, Thermorformed Blister

2) Various materials available: PVC, PS, PP, PE, PET, color sheet, flocked sheet

3) Thickness: according to your requirements and usage

Features:

1) We can tailor-make the most suitable blisters for your products,Blister Box, Plastic Blister, Vacuum Formed Blister, Thermorformed Blister

2) Various materials available: PVC, PS, PP, PE, PET, color sheet, flocked sheet

3) Thickness: according to your requirements and usage

Features:

1) We can tailor-make the most suitable blisters for your products,Blister Box, Plastic Blister, Vacuum Formed Blister, Thermorformed Blister

2) Various materials available: PVC, PS, PP, PE, PET, color sheet, flocked sheet

3) Thickness: according to your requirements and usage

Receiving a material in a can, drum or tin often requires the transfer to a syringe barrel or cartridge in order to dispense. This can be time consuming and messy resulting in wasted materials. Time spent filling barrels and cartridges could be better spent making products so we offer most adhesives and fluids in ready-to-use barrels and cartridges, air-free with the customers specified material.

Features:

1) We can tailor-make the most suitable blisters for your products,Blister Box, Plastic Blister, Vacuum Formed Blister, Thermorformed Blister

2) Various materials available: PVC, PS, PP, PE, PET, color sheet, flocked sheet

3) Thickness: according to your requirements and usage

By using specialist supplied packaging, we guarantee all supplied components are to the exact mix ratio's. This takes away any guesswork or the effort and time to measure and weight out mixes. All packaged components are supplied in sealed packs with labels displaying health and safety data, material information, fill date and shelf life.