Feature:

1.Very good insulator

2.Good thermal conductivity

3.Ultra soft and high compressibility

4.Natural tack

5.Easy to assembly

Application:

Electronic components:IC、CPU、MOS

LED、M/B、P/S、HEAT SINK、LCD-TV、N/B PC、PC、Telecom Device、Wireless Hub etc.

DDR II Module、DVD Applications、Hand-set applications etc.

| Test item | Test method | Unit | Test value | |

| JP-P600 value | JP-P520 value | |||

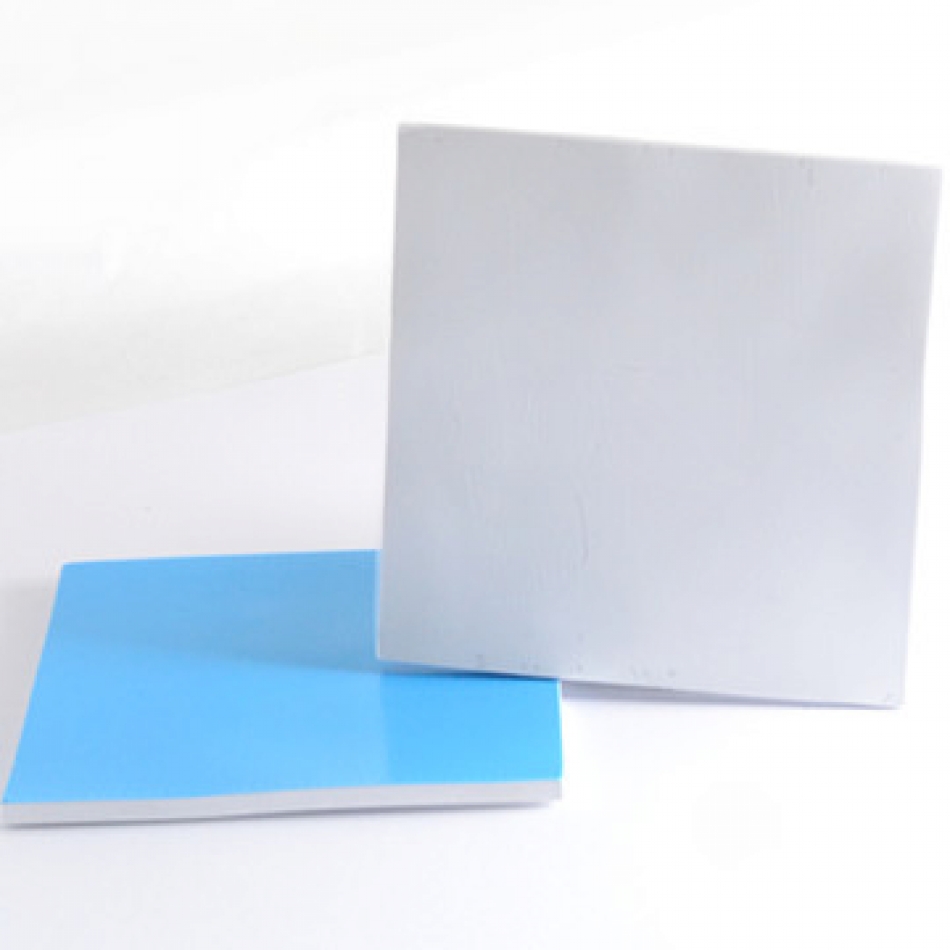

| Color | Visual | blue/red | yellow/blue | |

| Thickness | ASTM D374 | Mm | 0.25~5.0 | 0.25~5.0 |

| Density | ASTM D792 | g/cc | 2.8 | 2.8 |

| Hardness | ASTM D2240 | Shore C | 30±5 | 30±5 |

| Tensile Strength | ASTMD412 | KN/m | 0.4 | 0.4 |

| Continuous use Temp | EN344 | ℃ | -40~+220 | -40~+220 |

| Volume Resistivity | ASTM D257 | Ω-cm | 2.2×1011 | 3.2×1011 |

| Voltage Endu Ance | ASTM D149 | KV/mm | >5.0 | >5.0 |

| Thermal impedance | ASTM-D5470 | ℃in2/W | 0.2 | 0.3 |

| Flame Rating | UL-94 | V-0 | V-0 | |

| Conductivity | ASTM-D5470 | w/m-k | 6.0 | 5.2 |

Thickness :0.3mm-13mm

Dimension:200mm*400mm,300mm*300mm